We've all been there. A simple repair grinds to a halt because a single bolt absolutely refuses to budge. You're left with skinned knuckles, a lot of frustration, and a job that's suddenly way more complicated. This is exactly the scenario copper anti-seize was made to prevent. It's a lifesaver of a lubricant, packed with tiny copper particles, that stops metal parts from permanently fusing together under extreme heat and pressure.

What Copper Anti-Seize Is and Why Your Car Needs It

Think about what happens inside your car's engine bay or along its exhaust system. It's a brutal environment. Intense heat, constant vibration, and moisture create the perfect storm for metal parts to "seize" or "gall," which is just a technical way of saying they weld themselves together. When this happens, a simple bolt becomes a permanent fixture. That's where a good copper anti-seize compound becomes your best friend in the garage.

At its heart, it’s a high-quality grease loaded with fine copper flakes. When you brush it onto the threads of a bolt before installation, you create a protective, lubricating film. This barrier doesn't quit, even when temperatures skyrocket, ensuring the metal surfaces of the bolt and its housing never make the direct, damaging contact that leads to seizing.

Think of the copper particles as microscopic ball bearings. They fill the tiny gaps between the threads, preventing the metal-on-metal grinding that causes friction hot spots and galling. Even if the base grease burns off in extreme heat, those copper particles stick around to do their job.

This one simple step can save you a world of headaches down the road. It’s a trick of the trade for both seasoned DIYers and professional mechanics who can't afford to waste time on a seized fastener.

To give you a clearer picture, here's a quick rundown of what copper anti-seize brings to the table.

Copper Anti-Seize At a Glance

| Property | Description & Benefit |

|---|---|

| High-Temperature Resistance | Withstands extreme heat (up to 1800°F), making it perfect for exhaust manifolds, O2 sensors, and brake components. |

| Excellent Lubricity | Reduces friction, allowing for accurate and consistent torque application for critical fasteners. |

| Corrosion Protection | The grease base creates a barrier that shields threads from moisture, road salt, and rust. |

| Galling & Seizing Prevention | The copper solids prevent metal surfaces from welding together under pressure, ensuring easy disassembly. |

| Electrical Conductivity | Its conductive nature makes it a great choice for spark plug threads and ground connections. |

As you can see, it’s more than just a lubricant; it’s a crucial protective layer for your vehicle's most vulnerable hardware.

Key Benefits For Your Vehicle

The real value of copper anti-seize goes far beyond just preventing a stuck bolt. It offers a whole suite of protections that can extend the life of your parts and make future maintenance a breeze.

- No More Galling and Seizing: This is its main job. It stops thread damage on fasteners exposed to crazy high temperatures, like those holding on an exhaust manifold or turbocharger.

- Easy Disassembly, Every Time: Bolts that were coated with anti-seize come out smoothly years later. This saves you from the nightmare of snapped bolts and the hassle of drilling and tapping new threads.

- Keeps Rust at Bay: The grease base acts as a shield against moisture and road salt, which dramatically cuts down on corrosion for critical steel parts.

- Accurate Torque, Safer Clamping: By reducing friction, anti-seize helps you get a much more consistent and accurate torque reading. This is vital for components like lug nuts, where proper clamping force is a matter of safety.

It's no surprise that copper anti-seize compounds have become a staple in the automotive world, with a global market that has grown to USD 334.5 million. This demand is driven by mechanics and truck owners working on high-wear parts on everything from tailgate handles to exhaust systems on hardworking pickups like the F-Series or Silverado. A classic example you'll find in almost any professional shop is Loctite C5-A Copper Anti-Seize, which is formulated specifically for these tough, high-heat jobs. Understanding how it works is the first step to making your vehicle easier to service and avoiding expensive repairs later on.

What’s Actually Happening When You Use Copper Anti-Seize?

To really get why copper anti-seize is so essential, you have to look past the messy paste on your fingers and understand the science packed inside that little bottle. It’s not just another grease. It’s a powerful barrier designed to protect your fasteners in places where ordinary lubricants would just give up and burn away.

Think of it as a microscopic bodyguard for your bolts, preventing metal surfaces from fusing together in the harshest environments your vehicle can throw at them.

Let's zoom in on the threads of a bolt and nut. They look smooth to the naked eye, but under a microscope, they're a jagged landscape of tiny peaks and valleys. When you tighten a fastener, these little peaks—called asperities—grind against each other. This creates intense friction and heat, sometimes enough to literally weld the surfaces together. This process is called galling, and it’s the reason you end up with snapped bolts.

Copper anti-seize works by packing those valleys with soft copper particles. These particles create a buffer, acting like microscopic ball bearings that keep the metal peaks from ever making direct contact. They allow the surfaces to glide past each other smoothly, preventing that disastrous fusion.

It Laughs at Extreme Heat

One of the biggest reasons mechanics reach for copper anti-seize is its incredible ability to handle heat. A good quality formula is typically rated to withstand temperatures well over 1800°F (982°C). That’s a game-changer in automotive work, where many parts get far too hot for standard greases.

Just picture the bolts on your exhaust manifold. They're constantly blasted by hot exhaust gases and can easily glow red-hot—a temperature that would turn normal grease into smoke and ash in seconds. The grease carrier in anti-seize is actually designed to burn off.

The real magic is what stays behind: a dry film of tiny copper flakes. These metallic particles remain embedded in the threads, creating a lasting barrier that prevents seizing. Even after thousands of brutal heat cycles, that bolt will come out without a fight.

This high-heat superpower makes it the go-to choice for some of the toughest jobs on a car.

- Exhaust Manifold Bolts: These fasteners see some of the most extreme temperature swings on any vehicle.

- Turbocharger Flanges: The intense heat from a turbo demands a compound that won't simply vaporize.

- Brake Components: While not as scorching as an exhaust, brake parts get hot enough to cook off lesser lubricants, making anti-seize perfect for caliper pins and bolts.

A Lesson in Sacrificial Protection

Beyond creating a physical barrier, copper anti-seize provides another clever layer of defense: sacrificial protection. This is all about chemistry and preventing rust. When two different metals touch in the presence of moisture (think road salt and rain), the less "noble" metal will always corrode first.

This process is known as galvanic corrosion, and we can actually use it to our advantage. As it turns out, copper is less noble than the steel used in most bolts and studs.

This means if any water and salt get into the threads, the copper particles in the anti-seize will corrode before the steel does. They literally sacrifice themselves to protect the fastener, keeping its threads clean and strong. It's a huge benefit for parts that live a hard life, like suspension bolts and lug nuts.

A Note on Electrical Conductivity

Finally, you can’t talk about copper without mentioning electricity. Copper is a fantastic conductor, which can be a huge help in some spots and a major problem in others.

For example, a light coating on spark plug threads helps create a solid ground connection to the cylinder head, which can promote a cleaner, more consistent spark. But that same conductivity can be a liability. If you accidentally get a glob of copper anti-seize on the tip of an O2 sensor or inside an electrical connector, you risk causing a short circuit. That’ll almost guarantee a check engine light and a headache.

This is why careful, precise application is so important. A little goes a long way, and keeping it only where it belongs is non-negotiable.

Choosing the Right Anti-Seize Compound for the Job

Walk into any auto parts store, and you'll find a whole shelf of different anti-seize compounds staring back at you. It can be a little overwhelming. While copper anti-seize is a fantastic workhorse for most high-heat jobs, it's definitely not a magic bullet for every situation. In fact, using the wrong stuff can sometimes do more damage than doing nothing at all.

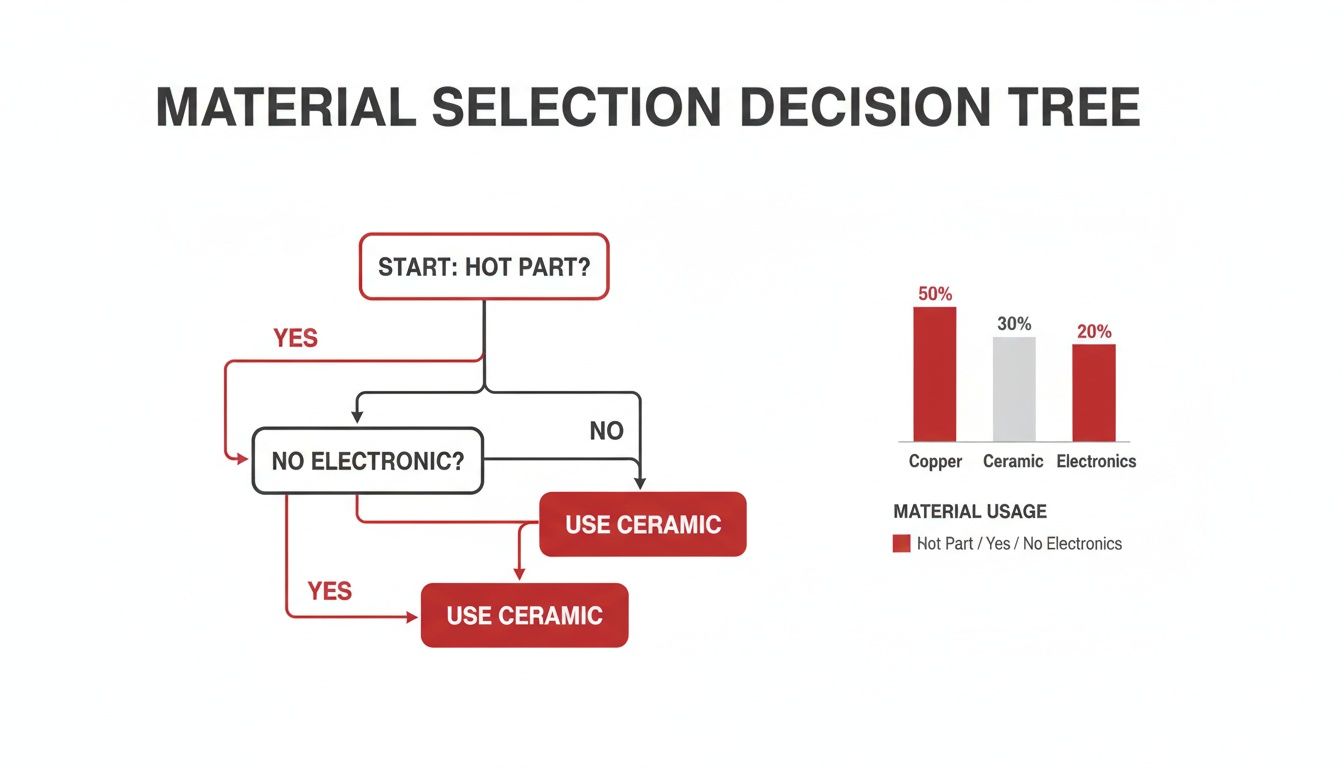

Making the right call boils down to a few key things: the metals you're working with, the temperatures they'll face, and whether there are any sensitive electronics nearby. Think of it like picking the right motor oil—different formulas are engineered for different jobs. Getting this right is what prevents costly mistakes like galvanic corrosion and ensures every fastener is protected for the long haul.

To help you sort it all out, here’s a quick rundown of the most common types of anti-seize you'll find and where they really shine in the garage.

Comparing Anti Seize Compounds for Automotive Use

| Anti Seize Type | Best For | Temperature Range | Key Advantage | Use With Caution |

|---|---|---|---|---|

| Copper | High-heat steel & iron fasteners (exhaust bolts, spark plugs) | Up to 1800°F | Excellent high-temp performance and conductivity. | On aluminum, magnesium, or near sensitive electronics. |

| Aluminum | General purpose, aluminum-to-aluminum or aluminum-to-steel | Up to 1600°F | Prevents galvanic corrosion with aluminum parts. | Not for the most extreme temperatures. |

| Nickel | Stainless steel, titanium, and extreme heat applications | Up to 2400°F | Chemically inert, handles extreme heat and pressure. | Typically more expensive than other types. |

| Ceramic | ABS sensors, O2 sensors, and fasteners near electronics | Up to 2000°F | Metal-free and non-conductive, preventing shorts. | Not ideal where electrical conductivity is needed. |

As you can see, each one has its specific role. Copper is the king for hot exhaust work, but ceramic is the only safe bet when you're working around modern vehicle electronics.

Why You Can't Just "Use Whatever"

So, what's the big deal? Why can't you just smear some copper anti-seize on an aluminum intake manifold bolt and call it a day? The answer is a nasty little process called galvanic corrosion.

This happens when two different metals touch each other while in the presence of an electrolyte (think moisture, road salt, or even just humidity). The metals essentially create a small battery. One metal (the anode) starts to corrode away at a rapid pace, while the other (the cathode) gets protected.

When you apply copper anti-seize to a steel bolt and thread it into an aluminum cylinder head, you’ve created a perfect storm for corrosion. The copper, steel, and aluminum form a galvanic cell, and the aluminum threads will be sacrificed, potentially ruining a very expensive part.

This is exactly why you have to match your anti-seize to your materials. For joining different metals, a nickel or ceramic formula is a much safer choice because they are more inert and won't kickstart that corrosive reaction.

This chart drives the point home: for hot mechanical parts away from electronics, copper is your go-to. But the moment sensors or wiring are involved, ceramic becomes the non-negotiable choice to prevent electrical problems.

The Go-To Choice for a Reason

The popularity of copper anti-seize isn't just shop talk; the numbers back it up. The global market for copper anti-seize paste is valued at around USD 0.5 billion and is expected to nearly double to USD 0.9 billion by 2034.

That growth is all thanks to its heavy use in industrial and automotive repair. Overall, metallic compounds like copper make up 72% of the anti-seize market, and copper’s impressive 35% share is a direct result of how well it performs in high-heat scenarios, like on the exhaust systems of a hard-working Toyota Tundra or Ford F-150.

This huge demand shows just how much mechanics rely on copper for the toughest jobs. It’s a proven tool, but like any tool, it has its place. Knowing when to grab the aluminum, nickel, or ceramic is what separates an okay repair from a truly professional one. Whether you're swapping out a single rusted bolt or doing a full overhaul, having the right automotive fasteners is just as critical as choosing the right compound to protect them.

Where to Use Copper Anti-Seize on Your Vehicle

Alright, so you know what this stuff is. But knowing where to actually put it is what really makes a difference between a frustrating Saturday afternoon and a smooth, successful repair. Copper anti-seize isn't something you slather everywhere; its real magic comes out in specific, high-stress spots on your car.

Think of the places that get scorching hot or are constantly fighting the elements. These are the areas where a little bit of this compound can save you from a world of hurt down the road. Let's walk through the key places where copper anti-seize will make your life a whole lot easier.

The Hottest Spots: Exhaust Manifold and Oxygen Sensor Threads

Nowhere on your vehicle sees more abuse than the exhaust system. The bolts holding your exhaust manifold to the cylinder head get baked by thousands of extreme heat cycles. It’s no wonder they love to rust solid and snap off. Applying a thin coat of copper anti-seize to those threads before you bolt everything up is one of the smartest things you can do.

When it’s time to replace a gasket or do engine work years later, those bolts will come out without a fight. You'll thank yourself for avoiding the nightmare of drilling out a broken stud. The same logic applies directly to your oxygen (O2) sensor threads.

Crucial Application Tip: When you're putting anti-seize on an O2 sensor, be surgical about it. A tiny dab on the threads is all you need. If any of this conductive paste gets on the sensor's tip, it will throw off its readings and likely trigger your check engine light.

Protecting Your Spark Plugs

Swapping out spark plugs should be a simple tune-up job. But it can turn into an absolute disaster if a plug seizes in the cylinder head. This can strip the threads right out of the head, turning a routine task into a costly, time-sucking repair. This is a huge risk with aluminum heads, where a steel spark plug can easily chew up the softer metal.

A very light smear of copper anti-seize on the spark plug threads gives you two big wins:

- It Stops Seizing: This is the big one. It guarantees the plugs will come out easily next time.

- It Helps Heat Transfer: The copper particles improve the connection between the plug and the head, which is critical for pulling heat away from the combustion chamber properly.

And again, be precise. Keep the anti-seize off the center electrode and the porcelain insulator to prevent a misfire.

Ensuring Reliable Brake Performance

Your brakes generate a ton of heat and are constantly getting blasted with water, road salt, and grime. It's the perfect recipe for rust and corrosion, which can cause parts to stick, bind up, and wear out unevenly. Copper anti-seize is your best friend here for several non-friction parts.

Put a thin film on the threads of caliper guide pins and the bolts that hold the caliper bracket. This keeps them from seizing, letting the caliper slide like it's supposed to for even pad wear. I also like to put a light coat on the hub face where the brake rotor sits. This stops the rotor from rusting itself to the hub, making your next brake job a breeze.

Lug Nuts (With a Word of Caution)

Using anti-seize on wheel studs is pretty common, but you absolutely have to know what you're doing. The lubricant in the anti-seize drastically reduces friction. If you just grab your torque wrench and tighten to the factory "dry" spec, you will seriously over-tighten the lug nut.

This can stretch or break wheel studs, damage the wheels, and even warp your brake rotors. Not good.

As a general rule of thumb, you need to reduce the manufacturer's dry torque spec by 15-25% when using anti-seize. Always check a reliable chart or your service manual for specific "wet" torque values.

The payoff is huge, especially if you live where roads are salted in the winter. Your wheels will never get stuck on the hubs again. Just be smart and adjust your torque.

Guarding Hinges, Latches, and Tailgates

It's not just about the high-heat components. Think about all the hinges, latches, and tailgate mechanisms on your vehicle that are constantly moving and exposed to rain and humidity. Over time, rust builds up in the pivot points and on the fastener threads, leading to annoying squeaks, stiff operation, or total failure.

Applying a dab of copper anti-seize to the bolt threads for door hinges, hood latches, and tailgate hardware keeps them from rusting in place. Fleet managers have been doing this for years to reduce maintenance on work trucks. In fact, the whole copper anti-seize market is expected to grow from USD 265 million to USD 306 million by 2031, largely because of its value in these kinds of automotive and industrial applications.

For the moving hinge pins themselves, you might need a different kind of lubricant. Our guide on how to properly lubricate car door hinges has some great tips to keep everything moving freely.

How to Apply Anti-Seize and Adjust Torque Correctly

Using copper anti-seize is more than just slathering some grease on a bolt. There’s a right way and a wrong way to do it, and getting it right is the secret to unlocking its full protective power without causing other headaches.

More importantly, you absolutely have to understand how this lubricant changes the physics of tightening a fastener. Ignoring this can lead to some seriously expensive mistakes.

Applying anti-seize is a game of precision, not volume. The old saying “less is more” is the golden rule here. You’re aiming for a thin, consistent layer on the threads—not a goopy mess covering the whole bolt. Too much compound just squeezes out, attracting dirt and turning into a grimy paste.

Step-by-Step Application Guide

A perfect application begins before you even pop the lid on the can. Clean threads are happy threads, and they’re essential for getting a solid connection and accurate torque.

- Clean Both Sets of Threads: Grab a wire brush and a can of brake cleaner or your favorite degreaser. Scrub all the dirt, rust, and old gunk off both the bolt's threads and the threads in the hole it's going into. Don't skip this step; it's critical for a reliable fix.

- Apply a Thin, Even Coat: Dip a small brush or the applicator into the copper anti-seize. You barely need any. Gently paint it onto the threads of the bolt, making sure you get a light, even film all the way around.

- Focus on the Threads: Be careful to keep the compound on the threads only. Getting it on the head or shank of the bolt is just messy, and you definitely want to keep it away from nearby sensors or electrical connectors.

Think of it like painting a model car, not a barn door. You're looking for a translucent, copper-colored film on the threads, not a thick, opaque glob.

This careful touch ensures the tiny copper particles are right where they need to be, ready to stop threads from galling and seizing together.

The Critical Role of Torque Adjustment

Okay, listen up, because this is easily the most important part of using any anti-seize product. The lubricants in the paste drastically reduce the friction between threads. While that’s great for preventing stuck bolts, it completely changes how your torque wrench behaves.

When a manufacturer gives you a torque spec, it's almost always a "dry" value. That means it’s calculated for clean, dry threads with no lubrication. The moment you add anti-seize, you’ve changed the equation. The same twisting force from your wrench will now produce way more clamping force on the fastener.

Using a dry torque spec on a lubricated bolt is a recipe for disaster. You will almost certainly over-tighten it, which can cause a world of hurt:

- Stripped Threads: You can easily rip the threads right out of a soft metal part, like an aluminum engine block or transmission case.

- Stretched or Broken Bolts: Overtightening can stretch a bolt beyond its designed limit, permanently weakening it or snapping it clean off.

- Warped Components: Too much clamping force can distort sensitive parts like brake rotors, valve covers, or intake manifolds.

As a rule of thumb, you need to reduce the factory dry torque spec by 15-25% when using copper anti-seize. But remember, this is just a guideline. The absolute best practice is to check the service manual for a specific "wet" or lubricated torque value if available.

Spending a few extra minutes on research is a whole lot better than dealing with a snapped bolt, a common problem on jobs like a front wheel bearing replacement where getting the torque right is crucial for safety.

Got Questions About Copper Anti-Seize?

Even after you know the basics, real-world questions always come up when you're elbow-deep in a project. Let's tackle some of the most common things mechanics and DIYers run into, so you can use this stuff with confidence and sidestep some expensive headaches.

Can I Use Copper Anti-Seize on Aluminum Parts?

This is a big one, and the short answer is a hard no. It's a really bad idea. When you put copper anti-seize on aluminum, you're setting the stage for a nasty process called galvanic corrosion.

Think of it like a tiny battery. When two different metals like copper and aluminum touch, especially with a little moisture or road salt in the mix, they create an electrical current. This current causes the weaker metal—the aluminum—to literally dissolve and corrode away. Before you know it, the threads on that expensive aluminum cylinder head or intake manifold could be completely ruined.

When working with aluminum, always reach for a nickel-based or, even better, a metal-free ceramic anti-seize. These are designed to be non-reactive, so they won't trigger that destructive chemical reaction.

Is Copper Anti-Seize Safe for O2 Sensors?

You have to be incredibly careful here. Many techs have used a tiny dab of copper anti-seize on O2 sensor threads for years to make them easier to remove later, but the risk of contamination is no joke.

Precision is everything. If even a tiny smear of that conductive copper anti-seize gets onto the sensor's tip or into the electrical connector, it can short it out or mess with its readings. That's a surefire way to trigger a check engine light and cause all sorts of performance problems.

To avoid the risk altogether, a lot of pros now use special, metal-free, high-temp anti-seize products made specifically for O2 sensors. It's the safer bet.

How Do I Clean Up Spilled Copper Anti-Seize?

If you've ever used this stuff, you know it has a magical ability to get on everything. It’s famously messy and a pain to clean up, especially off your skin and clothes. Soap and water usually just turn it into a greasy, glittery mess.

Here’s a better plan for cleanup:

- For Your Hands: Grab a waterless, citrus-based hand cleaner or a heavy-duty mechanic's soap. These are made to cut through the grease carrier and lift the copper flakes off your skin.

- For Car Paint: Don't delay. Gently wipe the spot with a clean microfiber towel and an automotive wax and grease remover. Whatever you do, don't use harsh solvents or anything abrasive—you'll scratch or strip your clear coat in a heartbeat.

- For Clothing: This is the tough one. Honestly, it might be a permanent stain. A powerful degreaser can sometimes help, but you'll often be left with a metallic shadow.

Does Copper Anti-Seize Expire or Go Bad?

A good quality copper anti-seize has a super long shelf life; it doesn't really "expire" like a carton of milk. Once it's on a bolt, it’s meant to last for the life of that connection.

In extreme heat, the grease that carries the copper particles might eventually burn off or dry out. But that’s okay. The microscopic copper flakes get trapped and embedded right in the threads, and they'll continue to act as a barrier to prevent the parts from seizing up.

You only need to worry about reapplying it if you take the parts apart again. If you do, the best practice is to clean the old gunk off with a wire brush and put on a fresh, thin coat before you torque everything back down.

Using the right technique is half the battle; the other half is using parts you can trust. For premium aftermarket components that are guaranteed to fit and built to last—from door handles to sensors—T1A Auto has you covered. Check out our catalog to find the reliable parts your project deserves at https://t1aauto.com.